Why Is the Duct Noise So Loud in the Fresh Air System?

There may be both installation issues and device issues.

Now many families have installed fresh air systems, and a large number of them choose fresh air systems to keep the indoor ventilation and fresh air when the doors and windows are closed to cut off the external noise. Especially in some residential areas with high traffic noise, if you want to rest, you must close the doors and windows to obtain a good sound environment, so the fresh air system is the main solution for ventilation.

However, unfortunately, many users find that the fresh air system also produces noise pollution, which is very distressing. There is an old saying in HVAC engineering, three parts are products, seven parts installation. In fact, the noise of the fresh air system equipment itself generally does not cause pollution. It is often due to the unreasonable installation that the noise of the fresh air system becomes louder, thus affecting the normal sound environment of people. So how do we change the installation process to control the noise of the fresh air system? Mainly from the following aspects:

Flexible air ducts connecting the fan and main ducting system.

1) The position of the host installation. The source of the noise of the fresh air system equipment is the built-in fan of the host. Therefore, under the premise of meeting the needs of use, the model with low noise should be selected as much as possible, which is the control of the noise source. After selecting the model, be sure to pay attention to the location of the host when installing the layout. Do not place the host computer in noise-sensitive rooms such as bedrooms and study rooms. It can be installed in noise-insensitive places such as kitchens and bathrooms. A living room that is further away from the main lounge area is also a good choice.

2) The installation of the host. In order to save the top space as much as possible, many users will require the host to be placed on the top, which is not suitable. There should be a certain distance between the host and the top floor. Similarly, the side of the host should not be close to the wall, and a certain distance should also be left. Vibration isolation measures should be taken for the boom of the host, such as the use of vibration isolation hooks, rubber gaskets between the fastening nuts and the mounting holes of the host. These measures are all to avoid the vibration of the main engine being transmitted to the building structure, thereby generating structure-borne noise.

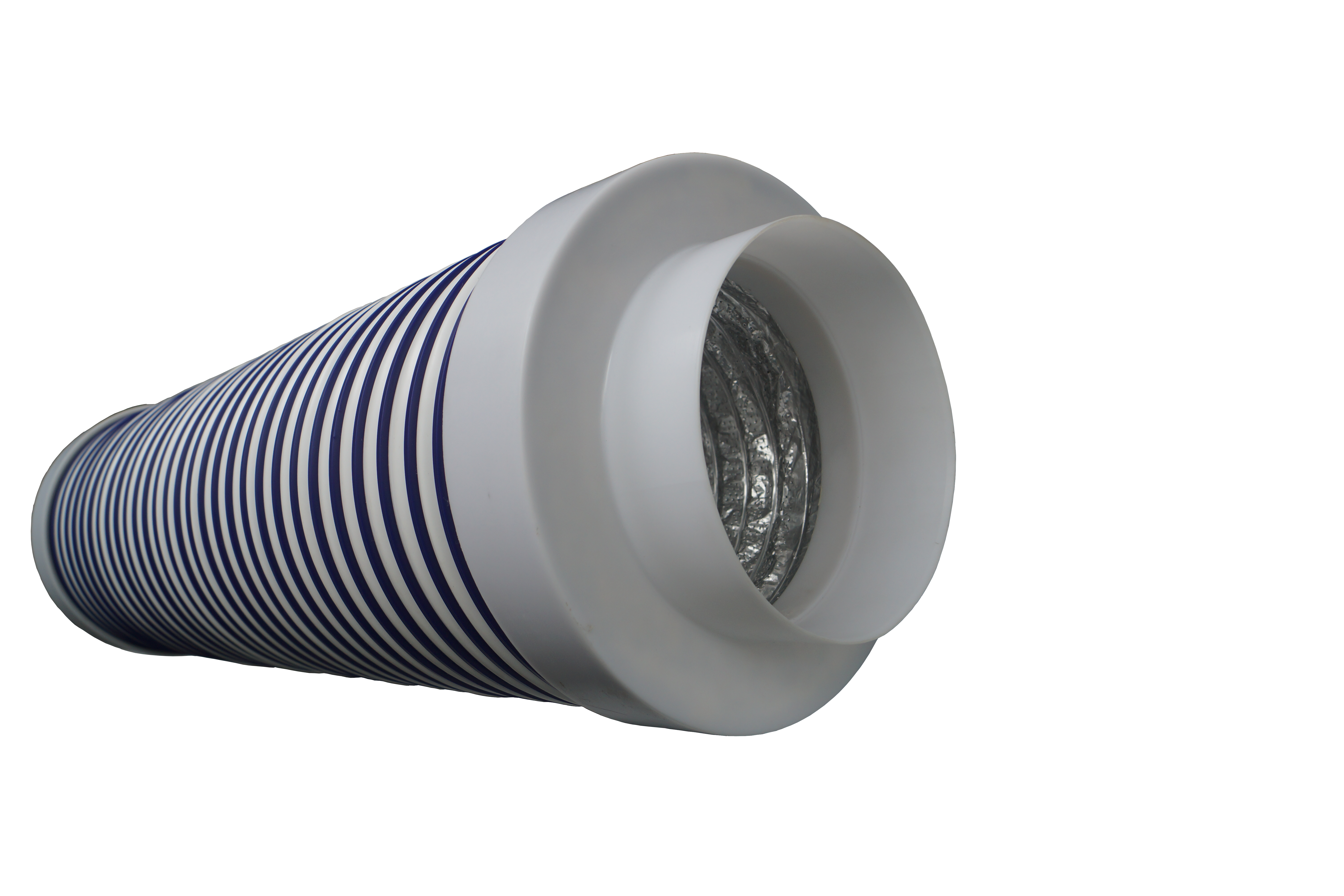

3) Installation of air ducts. The connection between the air duct and the air inlet and outlet of the host should use a soft connection. The soft connection should not be too long or too short, usually about 1m. This is to avoid transmitting the vibration of the host to the pipeline and causing the pipeline to resonate. When the main pipe is connected to the branch pipe, use the inclined tee instead of the straight tee. Try not to use right-angle elbows at the corners of the pipes, and use two 45-degree joints instead, and the airflow is too short and smoother. The indoor air supply and return air outlets and pipes must be connected with elastic flexible hoses. In addition to the consideration of vibration isolation, it is also convenient to match with the ceiling surface.

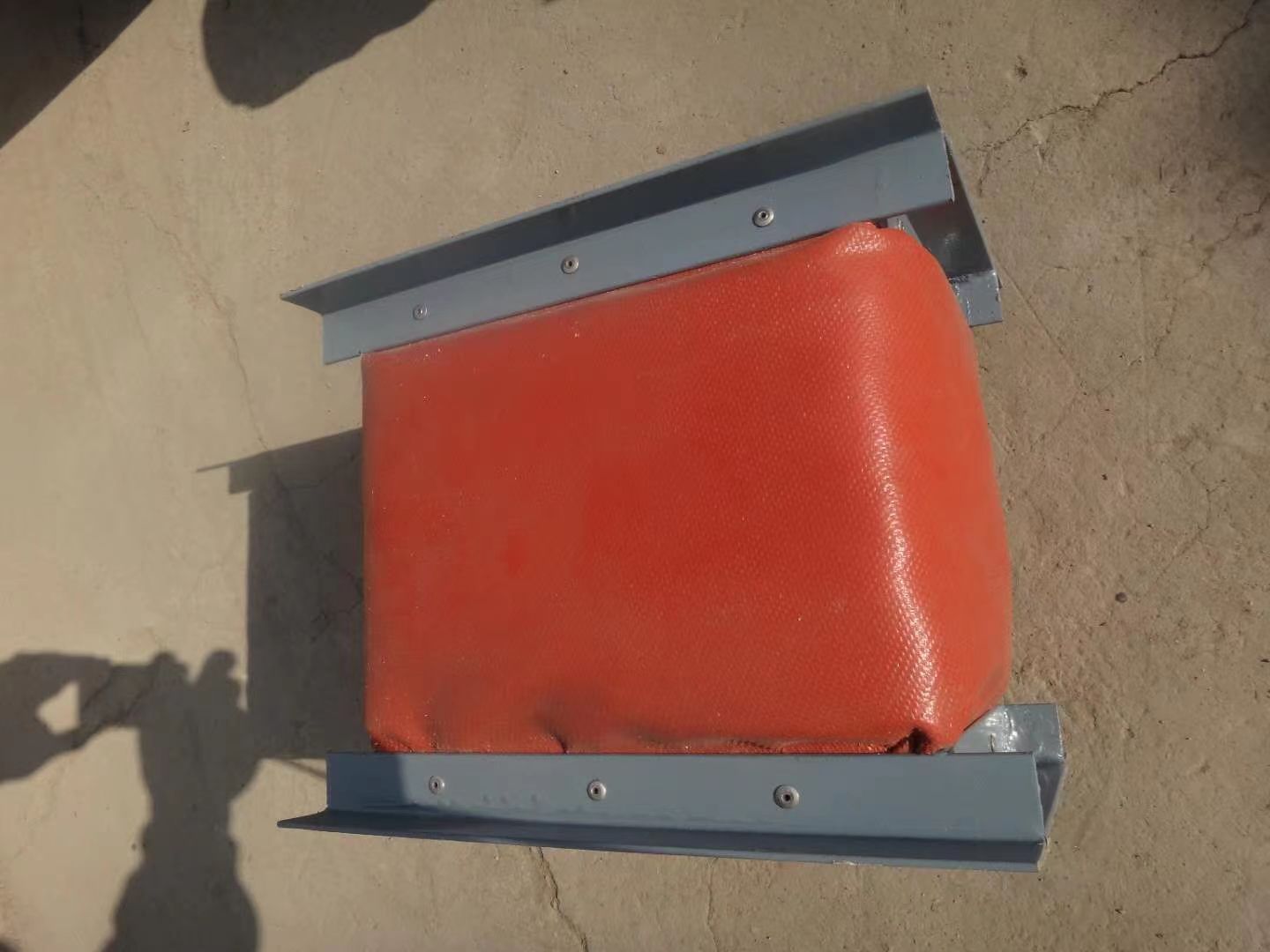

flexible joint (vibration isolation and adjust the height to match the ceiling)

4) Selection of bellows. The main function of the air distribution box is to change the air duct of the host into multiple strands and distribute them to each room, which is a shunt. The bellows can choose a product with a noise reduction function, which is similar to the static pressure box commonly used in HVAC engineering. On the one hand, part of the dynamic pressure can be converted into static pressure to make the air supply farther. On the one hand, it can be used as a universal joint to play a diverting role. In addition, it can eliminate noise and reduce noise, so a good air distribution box is essentially a static pressure box with multiple pipe joints.

5) Use of pipe mufflers. The installation environment is complex and often not perfect. In some special cases, it may cause high noise in a certain air outlet. At this time, first check whether the air outlet is blocked by foreign objects, and do a good job of dredging. If the ventilation is normal, but it is caused by airflow, or the noise from the host is radiated through the air duct, then a ventilation muffler is required. The muffler shell is lined with sound-absorbing cotton, which can reduce noise while allowing airflow to pass, and has never achieved the effect of noise reduction.

6) Sound insulation ceiling. Whenever a fresh air system is used, a ceiling must be made to achieve a decorative effect. Today, people have higher and higher requirements for the quality of life, and the requirements for the acoustic environment are also higher and higher. Therefore, if you need to do a suspended ceiling, it is very necessary to do a sound insulation ceiling. Compared with the decorative ceiling, the sound insulation ceiling has strengthened the sound insulation performance, which can not only greatly reduce the mechanical noise of the main engine of the fresh air system, but also have a better protection effect on the living noise upstairs. For example, due to the thin floor and insufficient sound insulation, the upstairs TV sound and speech sound penetrated into radiation; the impact noise caused by children running and jumping, tables and chairs moving, etc. In addition, the position of the sound insulation ceiling close to the main engine needs to be set up with a movable inspection port. The movable port should be reasonably designed, and the sealing should be better to avoid sound leakage.

Products from our company can help you with building a quiet home!

https://www.flex-airduct.com/flexible-composite-pvc-al-foil-air-duct-product/

https://www.flex-airduct.com/expansion-joints-fabric-expansion-joints-product/

https://www.flex-airduct.com/aluminum-alloy-acoustic-air-duct-product/

Post time: Oct-31-2022