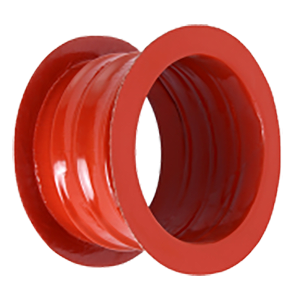

Boleng bo Phahameng bakeng sa Single Sphere Carbon Steel Zinc Plated Rubber Joint

Re lula re lumela hore sebopeho sa motho se etsa qeto ea boleng ba lihlahisoa tsa boleng bo holimo, lintlha li etsa qeto ea hore lihlahisoa ke tsa boleng bo holimo, 'moho le moea oa SEBELISA, O SEBELISANG LE O HLAHANG OA TŠEBELETSO bakeng sa boleng bo phahameng bakeng sa Single Sphere Carbon Steel Zinc Plated Rubber Expansion Joint, Morero oa feme ea rona. e ka ba ho fana ka lihlahisoa tsa boleng bo holimo le litharollo tse nang le boleng bo sebetsang haholo. Re labalabela ho sebetsa le uena!

Re lula re lumela hore sebopeho sa motho se etsa qeto ea boleng ba lihlahisoa tsa boleng bo holimo, lintlha li etsa qeto ea hore lihlahisoa tsa boleng bo holimo, 'moho le moea oa SEBELISA, O SEBELISANG LE O HLAHANGChaena ea Katoloso ea Rabara e Kopanetsoeng le Kopanelo ea Rabara, Sepheo sa rona ke ho thusa bareki ho hlokomela lipakane tsa bona. Re etsa matsapa a maholo ho fihlela boemo bona ba ho hlola 'me re u amohela ka tieo hore u be le rona. Ka mantsoe a mang, ha u re khetha, u khetha bophelo bo phethahetseng. Rea u amohela ho etela fektheri ea rona 'me u amohele taelo ea hau! Bakeng sa lipotso tse ling, u seke oa tsilatsila ho ikopanya le rona.

Tšebeliso ea Manonyeletso a Katoloso ea Lesela le sa Metal

Manonyeletso a Katoloso ea Lesela le Senyehileng a nang le li-revers ke mofuta o mocha oa manonyeletso a se nang tšepe. Melemo e tloaelehileng ke e bobebe, e bobebe, ea hermetic, mocheso o phahameng oa ho sebetsa, anti-corrosive, sekhahla se seholo sa matšeliso le ho kenya habonolo. Li loketse bakeng sa khokahano e feto-fetohang lipakeng tsa libapali tse fapaneng tsa moea, li-ducts le liphaephe; e ka lefella deformation ea mocheso oa pipework le ho lokolla khatello ea lipeipi; fokotsa kapa ho fokotsa ho sisinyeha ha liphaephe; le ho etsa hore ho hlongoa tsamaiso eohle ho be bonolo.

Manonyeletso a Katoloso ea Lesela le Kokotehileng a fapane le a tloaelehileng ao e seng a tšepe. E entsoe ka lera le le leng kapa lihlopha tse ngata tsa rabara le masela, laminated tlas'a mocheso o phahameng le khatello; li-revers li fetoloa le ho bōptjoa hang ka theknoloji e khethehileng, e fapaneng le mosebetsi oa matsoho bakeng sa ho hlahisa manonyeletso a tloaelehileng a ho atolosa lesela-- gluing, roka, ho koahela le ho hatella flange. 'Me lithekniki tse khethehileng li etsa hore manonyeletso a rona a katoloso a hlōle lintlha tse fokolang tsa manonyeletso a tloaelehileng a kang laminated e sa tieang, eseng ea hermetic, e lutlang, e boima, e thata bakeng sa ho kenya le ho boloka.

Manonyeletso a Katoloso ea Lesela le Senyehileng a hokahana le li-flange ka lera la eona la rabara holim'a li-revers, khokahano e na le hermetic haholo; 'me e ka boloka khatello ea ho sebetsa ea max 2MPa. The axial compression ratio, radial le rotational shifting e molemo haholo ho feta maqhama a tloaelehileng a ho atolosa. Manonyeletso a rona a Katoloso ea Lesela le Senyehileng a loketse haholo bakeng sa libapali tsa moea, liphaephe ho fokotsa ho sisinyeha ha sistimi, lerata le khatello ea maikutlo. Ke likarolo tse ntle ka ho fetisisa tseo u lokelang ho ba le tsona bakeng sa sistimi ea hau.

Re sebelisa mefuta e fapaneng ea masela ho etsa manonyeletso a ho atolosa ho latela litlhoko tsa bareki ba rona le maemo a ts'ebeliso, joalo ka rabara ea silicon, rabara ea fluorine, Ethylene-Propylene-Diene Monomer(EPDM).

E khothalelitsoeng Kopo

● Indasteri ea tšebetso

● Indasteri ea peterole

● Indasteri ea lik'hemik'hale

● Indasteri ea meriana

● Mecha ea litaba e chefo, e kotsi, ea lik'hemik'hale

● Mesaletsa le ho chesoa ha litšila

● Calcination

● Phokotso

● Indasteri ea oli le khase

● Theknoloji ea ho hloekisa

● Theknoloji ea setsi sa motlakase

● Indasteri ea pampiri le pampiri

● Ho hlahisa le ho sebetsa ka tšepe

● Indasteri ea samente

● Likotopo tsa khase ea flue

● Mehaho ea metsi a belisang le liphahlo

● Ho kenella ka lipeipi

● Mela ea tšebetso

● Mekotla

● Liindasteri tse nang le litlhoko tse phahameng

Melemo

● Ho fokotsa mesi ea tšilafalo

● Tšebetso e sireletsehileng

● Phokotso e kholo ea tšebeliso ea matla a mantlha

● Bophelo bo bolelele ba tšebeletso, ho apara ka tlaase

● Nako ea ho phomola e reriloeng esale pele

● E fumaneha e le puseletso litsamaisong tse teng

● Ho tenyetseha habonolo

● Ho hanyetsa lik'hemik'hale tse phahameng

● Ho fokotsa mocheso

● Matla a fokolang a ho arabela

※ E etselitsoe ho lumellana le maemo a sebele a ho sebetsa le lisebelisoa ha u li kopa.

| Thepa ea Lesela | Mesebetsi ea bopaki ba boemo ba leholimo | Mesebetsi ea 'mele | Mesebetsi ea lik'hemik'hale | mocheso o sebetsang | Eseng bakeng sa | |||||||||||||||||

| ozene | oxide | khanya ea letsatsi | mahlaseli | botenya ba lesela | khatello ea maikutlo | axial compression ratio (%) | axial stretch ratio (%) | ho fetoha ha radial (%) | loketseng bakeng sa maro | E chesang H₂SO₄ | E chesang H₂SO₄ | Hot HCL | Hot HCL | E se nang metsi ammonia | NaOH | NaOH | sebetsa mocheso oa mocheso | Max cotinious mocheso o sebetsang | nakoana max mocheso o sebetsang | |||

| lesela + lera la tiiso ea khase | Khatello e ntle | Khatello e mpe | <50% | >50% | <20% | >20% | <20% | >20% | ||||||||||||||

| EPDM rabara (EPDM) | molemo | molemo | molemo | molemo | 0.75 ~ 3.0 limilimithara | boholo ba34.5 mets14.5 | boholo ba34.5 mets14.5 | 60% | 10-20% | 5-15% | khase e senyang metsoako ea manyolo khase e akaretsang | loketseng (e ntle) | karolelano kapa mafutsana | karolelano | mafutsana | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | -50℃148℃ | 148℃ | 176 ℃ | Aliphatic hydrocarbons Li-hydrocarbon tse nkhang hamonate |

| Rabara ea Silicone(SL) | molemo | molemo | molemo | karolelano | 0.6-3.0 limilimithara | boholo ba34.5 mets14.5 | boholo ba34.5 mets14.5 | 65% | 10%~25% | 5%~18% | khase e akaretsang | mafutsana | mafutsana | mafutsana | mafutsana | mafutsana | loketseng (e ntle) | karolelano | -100℃240℃ | 240 ℃ | 282 ℃ | Oli e qhibilihisitsoeng asiti alkali |

| Chlorosulfonated rabara ea polyethylene (CSM/Hypalon) | molemo | molemo | molemo | molemo | 0.65 ~ 3.0 limilimithara | boholo ba34.5 mets14.5 | boholo ba34.5 mets14.5 | 60% | 10-20% | 5-15% | khase e senyang metsoako ea manyolo khase e akaretsang | loketseng (e ntle) | karolelano | karolelano | mafutsana | karolelano | loketseng (e ntle) | loketseng (e ntle) | -40℃107℃ | 107℃ | 176 ℃ | Hydrogen chloride e kopantsoeng |

| Plastiki ea Teflon (PTFE) | molemo | molemo | molemo | molemo | 0.35-3.0 limilimithara | boholo ba34.5 mets14.5 | boholo ba34.5 mets14.5 | 40% | 5%~8% | 5%~10 | Boholo ba khase e senyang metsoako ea manyolo | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | -250℃260℃ | 260 ℃ | 371℃ | Ho hanyetsa ho apara hampe |

| Fluororubber(FKM)/Viton | molemo | molemo | molemo | karolelano | 0.7-3.0 limilimithara | boholo ba34.5 mets14.5 | boholo ba34.5 mets14.5 | 50% | 10-20% | 5-15% | khase e senyang metsoako ea manyolo khase e akaretsang | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) kakaretso | mafutsana | loketseng (e ntle) | karolelano | -250℃240℃ | 240 ℃ | 287 ℃ | ammonia |

Re lula re lumela hore sebopeho sa motho se etsa qeto ea boleng ba lihlahisoa tsa boleng bo holimo, lintlha li etsa qeto ea hore lihlahisoa ke tsa boleng bo holimo, 'moho le moea oa SEBELISA, O SEBELISANG LE O HLAHANG OA TŠEBELETSO bakeng sa boleng bo phahameng bakeng sa Single Sphere Carbon Steel Zinc Plated Rubber Expansion Joint, Morero oa feme ea rona. e ka ba ho fana ka lihlahisoa tsa boleng bo holimo le litharollo tse nang le boleng bo sebetsang haholo. Re labalabela ho sebetsa le uena!

Boleng bo Phahameng bakeng saChaena ea Katoloso ea Rabara e Kopanetsoeng le Kopanelo ea Rabara, Sepheo sa rona ke ho thusa bareki ho hlokomela lipakane tsa bona. Re etsa matsapa a maholo ho fihlela boemo bona ba ho hlola 'me re u amohela ka tieo hore u be le rona. Ka mantsoe a mang, ha u re khetha, u khetha bophelo bo phethahetseng. Rea u amohela ho etela fektheri ea rona 'me u amohele taelo ea hau! Bakeng sa lipotso tse ling, u seke oa tsilatsila ho ikopanya le rona.