Ukwandiswa kwaMajoyinti / Ukwandiswa kweFabric Joints

Ukusetyenziswa kweZidibaniselwano zoKwandiswa kweFabric ezingezizo ezentsimbi

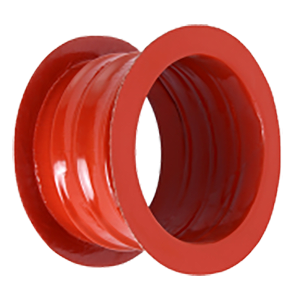

Ukwandiswa Kwelaphu eliKotileyo Izidibanisi ezineenguqu luhlobo olutsha lweendawo ezingezona zentsimbi zokwandiswa. Izibonelelo eziqhelekileyo zikhaphukhaphu, zithambile, i-hermetic, ubushushu obuphezulu bokusebenza, i-anti-corrosive, ireyithi yembuyekezo enkulu kunye nofakelo olulula. Zifanele uxhulumaniso oluguquguqukayo phakathi kweefeni ezahlukeneyo ze-ventilation, imibhobho kunye nombhobho; inokuhlawula i-thermal deformation yombhobho kwaye ikhulule uxinzelelo lwemibhobho; ukunciphisa okanye ukunciphisa ukungcangcazela kombhobho; kwaye wenze ufakelo lwenkqubo yonke lula.

Ukwandiswa kwelaphu elidityanisiweyo Izihlanganisi zokwandiswa kwelaphu lahlukile kwezo zemveli non-metal ukwandiswa joint. Yenziwe ngoluhlu olulodwa okanye iileya ezininzi zeerubha kunye neendwangu, i-laminated phantsi kobushushu obuphezulu kunye noxinzelelo; iirevers ziguqulwa zibe kanye ngobuchwephesha obukhethekileyo, obahlukileyo kumsebenzi wobugcisa wokuvelisa amalungu okwandisa ilaphu esintu---- ukuncamathelisa, ukuthunga, ukugquma kunye nocinezelo lweflange. Kwaye ubugcisa obukhethekileyo benza ukuba amalungu ethu okwandisa aphumelele iindawo ezibuthathaka zokwandiswa kwamalungu afana ne-laminated engagungqiyo, hayi i-hermetic, evuzayo, enzima, enzima yofakelo kunye nokugcinwa kwayo.

I-Corrugated Fabric Expansion Joints idibanisa kwiiflange kunye nomgca wayo werabha kwi-revers, uxhumano luyi-hermetic kakhulu; kwaye inokugcina uxinzelelo oluphezulu lwe-2MPa yokusebenza. I-axial compression ratio, i-radial kunye ne-rotation shifting ingcono kakhulu kunamajoyini okwandiswa kwendabuko. Izixhobo zethu zoKwandiswa kweLaphu eliThwetyelwe zilungele kakhulu abalandeli bokungenisa umoya, imibhobho yokunciphisa ukungcangcazela kwenkqubo, ingxolo kunye noxinzelelo. Zezona ndawo zilungileyo ofanele ube nazo kwinkqubo yakho.

Sisebenzisa iintlobo ezahlukeneyo zamalaphu ukwenza amajoyina okwandisa ngokweemfuno zobugcisa zabathengi bethu kunye neendawo zokusebenzisa, ezifana nerubha yesilicone, irabha ye-fluorine, i-Ethylene-Propylene-Diene Monomer (EPDM).

Isicelo esicetyiswayo

● Ushishino lwenkqubo

● Ushishino lwepetrochemical

● Ishishini lemichiza

● Ishishini lamayeza

● Imidiya enetyhefu, eyingozi, enekhemikhali

● Intsalela kunye nokutshiswa kwenkunkuma

● Ukubala

● Ukunciphisa

● Ishishini leoli negesi

● Iteknoloji yokusulungekisa

● Iteknoloji yeplanti yombane

● Ishishini lempuphu nephepha

● Ukuveliswa kwesinyithi kunye nokulungiswa

● Ishishini lesamente

● Imibhobho yerhasi enomkhuhlane

● Iibhoyiri kunye neendawo zokukhupha

● Ukungena kwemibhobho

● Imigca yenkqubo

● Iimfumba

● Amashishini aneemfuno eziphezulu

Iingenelo

● Ukukhutshwa kongcoliseko okucuthiweyo

● Ukusebenza ngokukhuselekileyo

● Unciphiso olumandla kusetyenziso lwamandla lokuqala

● Ubomi benkonzo ende, ukunxiba okuphantsi

● Ixesha lokuphumla eliqikelelwayo

● Ifumaneka njenge-retrofit kwiisistim ezikhoyo

● Ukuba bhetyebhetye kakuhle

● Ukumelana neekhemikhali eziphezulu

● Ukuncipha kokulahlekelwa bubushushu

● Amandla okusabela amancinci

※ Yenzelwe ukuba ilingane iimeko zokusebenza kunye nezixhobo xa uceliwe.

| Ilaphu Material | Imisebenzi yobungqina bemozulu | Imisebenzi yomzimba | Imisebenzi yeMichiza | ubushushu bokusebenza | Hayi ngenxa | |||||||||||||||||

| ozene | ioksidi | ukukhanya kwelanga | imitha | ubukhulu belaphu | uluhlu loxinzelelo | i-axial compression ratio (%) | i-axial stretch ratio (%) | ukutshintsha kweradial (%) | ifanelekile ulwelo | Kushushu H₂SO₄ | Kushushu H₂SO₄ | I-HCL eshushu | I-HCL eshushu | Ayinamanzi ammonia | NAOH | NAOH | ukusebenza uluhlu lobushushu | Ubuninzi obuqhubekayo ubushushu bokusebenza | ubuninzi bexeshana ubushushu bokusebenza | |||

| ilaphu + umaleko wokutywina wegesi | Uxinzelelo oluhle | Uxinzelelo olubi | <50% | >50% | <20% | >20% | <20% | >20% | ||||||||||||||

| Irabha ye-EPDM (EPDM) | kulungile | kulungile | kulungile | kulungile | 0.75 ~ 3.0mm | max34.5 umz14.5 | max34.5 umz14.5 | 60% | 10-20% | 5-15% | igesi edlayo izinyibilikisi eziphilayo igesi jikelele | ezifanelekileyo (kulungile) | umndilili okanye ihlwempu | umndilili | ihlwempu | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | -50℃148℃ | 148℃ | 176℃ | Aliphatic hydrocarbons Iihydrocarbons ezinuka kamnandi |

| Irabha yeSilicone(SL) | kulungile | kulungile | kulungile | umndilili | 0.6-3.0mm | max34.5 umz14.5 | max34.5 umz14.5 | 65% | 10%~25% | 5%~18% | igesi jikelele | ihlwempu | ihlwempu | ihlwempu | ihlwempu | ihlwempu | ezifanelekileyo (kulungile) | umndilili | -100℃240℃ | 240℃ | 282℃ | Ioli yokunyibilikisa iasidi ialkali |

| I-Chlorosulfonated irabha ye-polyethylene (CSM/Hypalon) | kulungile | kulungile | kulungile | kulungile | 0.65-3.0mm | max34.5 umz14.5 | max34.5 umz14.5 | 60% | 10-20% | 5-15% | igesi edlayo izinyibilikisi eziphilayo igesi jikelele | ezifanelekileyo (kulungile) | umndilili | umndilili | ihlwempu | umndilili | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | -40℃107℃ | 107℃ | 176℃ | I-hydrogen chloride egxininisiweyo |

| Iplastiki yeTeflon (PTFE) | kulungile | kulungile | kulungile | kulungile | 0.35 ~ 3.0mm | max34.5 umz14.5 | max34.5 umz14.5 | 40% | 5%~8% | 5%~10 | Uninzi lwerhasi eyonakalisayo izinyibilikisi eziphilayo | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | -250℃260℃ | 260℃ | 371℃ | Ukumelana nokunxiba kakubi |

| Fluororubber(FKM)/Viton | kulungile | kulungile | kulungile | umndilili | 0.7-3.0mm | max34.5 umz14.5 | max34.5 umz14.5 | 50% | 10-20% | 5-15% | igesi edlayo izinyibilikisi eziphilayo igesi jikelele | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) | ezifanelekileyo (kulungile) jikelele | ihlwempu | ezifanelekileyo (kulungile) | umndilili | -250℃240℃ | 240℃ | 287℃ | ammonia |