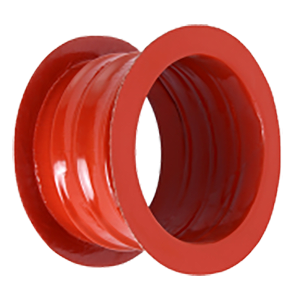

Amalungu okwandisa angeyintsimbi

Amalungu okwandisa angeyintsimbizikwabizwa ngokuba yi-non-metallic compensator kunye ne-compensators zelaphu, eziluhlobo lwembuyekezo. Izinto ezidityanisiweyo ezingezizo ezentsimbi zizilaphu zefiber, irabha, izixhobo zobushushu obuphezulu njalo njalo. Iyakwazi ukuhlawulela ukungcangcazela kwabalandeli kunye nemibhobho yomoya kunye nokuguqulwa kwemibhobho.

Isicelo:

Amalungu okwandisa angeyontsimbi angakwazi ukuhlawulela i-axial, icala elisecaleni kunye ne-angular, kwaye aneempawu zokungatyhala, uyilo olulula lokuthwala, ukuxhathisa ukubola, ukumelana nobushushu obuphezulu, ukunciphisa ingxolo kunye nokunciphisa ukungcangcazela, kwaye zifaneleke ngakumbi imigudu yomoya oshushu kunye nomsi. kunye nemibhobho yothuli.

Indlela yokudibanisa

- Uqhagamshelwano lweFlange

- Ukudibanisa nombhobho

Uhlobo

- Uhlobo oluthe ngqo

- Uhlobo lweDuplex

- Uhlobo lwe-engile

- Uhlobo lwesikwere

I-1 Imbuyekezo yokwandiswa kwe-thermal: Iyakwazi ukuhlawulela kwiindlela ezininzi, ezingcono kakhulu kune-comensator yensimbi enokuhlawula kuphela ngendlela enye.

2. Imbuyekezo yempazamo yokufakela: Ekubeni impazamo yenkqubo ayinakuphepheka kwinkqubo yoxhulumaniso lombhobho, i-fiber compensator inokuhlawula ngcono impazamo yokufakela.

I-3 Ukunciphisa ingxolo kunye nokunciphisa i-vibration: Ilaphu lefiber (i-silicone cloth, njl.) kunye nomzimba we-cotton wokufakelwa kwe-thermal unemisebenzi ye-sound absorption kunye ne-vibration isolation transmission, enokunciphisa ngokufanelekileyo ingxolo kunye nokugubha kweebhoyili, iifeni kunye nezinye iinkqubo.

4 Akukho nto ibuyela umva: Ekubeni eyona nto iphambili ililaphu lefiber, ayisasazeki kakuhle. Ukusebenzisa i-fiber compensator kwenza uyilo lube lula, kunqanda ukusetyenziswa kwenkxaso enkulu, kwaye konga izinto ezininzi kunye nomsebenzi.

5. Ukumelana nokushisa okuphezulu okuphezulu kunye nokumelana nokugqwala: Izinto ezikhethiweyo ze-fluoroplastics kunye ne-silicone zinokumelana nokushisa okuphezulu kunye nokuxhathisa ukubola.

6. Ukusebenza kakuhle kokutywinwa: Kukho imveliso epheleleyo kunye nenkqubo yokuhlanganisa, kwaye i-fiber compensator inokuqinisekisa ukuba akukho kuvuza.

7. Ubunzima bokukhanya, isakhiwo esilula, ukufakela okulula kunye nokugcinwa.

8. Ixabiso liphantsi kunomhlawuleli wesinyithi

Ulwakhiwo olusisiseko

1 ulusu

Ulusu ngowona mzimba wokwandiswa kunye nokucutheka komdibaniso ongeyontsimbi yokwandiswa. Iqulunqwe ngamaleko amaninzi erabha ye-silicone okanye i-high-silica polytetrafluoroethylene kunye nokusebenza okugqwesileyo kunye noboya beglasi obungena-alkali. Yimathiriyeli ehlanganisiweyo yokutywina ephezulu. Umsebenzi wayo kukufunxa ukwanda kunye nokuthintela ukuvuza komoya kunye namanzi emvula.

2 umnatha wentsimbi engenasici

I-mesh yensimbi engenasici yintsimbi ye-non-metallic expansion joint, ekhusela i-sundries kwindawo ejikelezayo ukuba ingene kwi-joint yokwandisa kunye nokuthintela izinto zokufakelwa kwe-thermal kwi-joint yokwandisa ukubaleka ngaphandle.

3 Umqhaphu we-insulation

Ikotoni yokufakelwa kwe-thermal ithathela ingqalelo imisebenzi emibini yokufakelwa kwe-thermal kunye nokuqina komoya kwamalungu okwandisa angeyintsimbi. Yenziwe ngelaphu legilasi yefiber, ilaphu le-silica ephezulu kunye neentlobo ezahlukeneyo zomqhaphu wokufakelwa kwe-thermal. Ubude nobubanzi bayo buhambelana nesikhumba sangaphandle. Ubude obuhle kunye namandla okuqina.

4 Umaleko we-insulation filler

I-thermal insulation filler layer iyona siqinisekiso esiphambili se-thermal insulation ye-non-metallic expansion joints. Yenziwe ngezinto ezinokumelana nobushushu obuphezulu njengemicu ye-ceramic enemigangatho emininzi. Ubunzima bayo bunokumiselwa ngokubala kokutshintshwa kobushushu ngokweqondo lokushisa lendawo ejikelezayo kunye ne-thermal conductivity yezinto ezichasene nobushushu obuphezulu.

Iirack ezi-5

Isakhelo yi-contour bracket ye-non-metallic expansion joints ukuqinisekisa ukomelela okwaneleyo kunye nokuqina. Izinto zesakhelo kufuneka zitshintshwe kwiqondo lokushisa eliphakathi. Ngokuqhelekileyo kwi-400. Sebenzisa i-Q235-A 600 ngaphantsi kwe-C. Ngaphezulu kwe-C yenziwe ngensimbi engenasici okanye i-heat-resistant steel. Isakhelo ngokubanzi sinomphezulu we-flange ohambelana nombhobho weflue odityanisiweyo.

6 iibhedi

I-baffle kukukhokela ukuhamba kunye nokukhusela i-thermal insulation layer. Izinto eziphathekayo kufuneka zihambelane nobushushu obuphakathi. Iimathiriyeli kufuneka zibe ngumhlwa kwaye zingagugi. I-baffle ayifanele ichaphazele ukufuduka komdibaniso wokwandisa.

Ixesha lokuposa: Nov-10-2022